Securing Achievement: Innovative Uses of Vacuum-sealed Flanges in Manufacturing

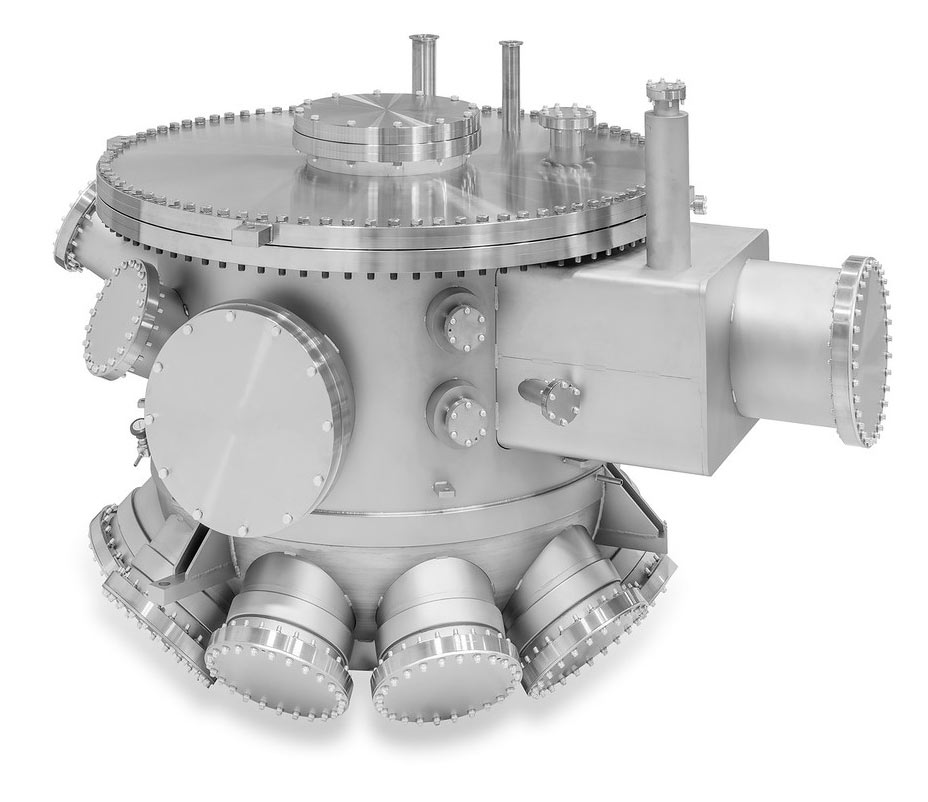

In a fast-paced world of manufacturing and engineering, vacuum flanges play a crucial role in forming airtight seals that are necessary for various processes. These innovative components are created to connect vacuum systems with complementary equipment, maintaining that vacuum integrity is maintained throughout operations. As businesses continue to seek ways to improve efficiency and reduce contamination, the demand for dependable sealing solutions like vacuum flanges has not been more pressing.

From chip fabrication to chemical processing, the applications of vacuum flanges are broad and important. They are instrumental in industries that count on high-precision environments to optimize product quality and uphold safety standards. Grasping how these flanges work and their versatile uses across different sectors not only highlights their importance but also reveals the evolving landscape of industrial technology. By exploring the multifaceted applications of vacuum flanges, we can obtain profound insights into how they aid to the success of contemporary manufacturing processes.

Grasping Vacuum Connections

Sealing flanges are crucial parts in devices that operate under vacuum conditions. They provide the critical sealing mechanism to maintain the stability of the vacuum by preventing leakage of gases. Usually made from elements like aluminum or aluminum, these flanges provide robust performance and tolerance to various elements, making them appropriate for a variety of industrial applications.

In factory environments, vacuum flanges are often used in operations such as electronic manufacturing, material processing, and R&D. Their structure enables swift installation and removal, streamlining maintenance and interchange. The ability to form a strong connection is imperative in these situations, where any failure in the vacuum can lead to serious problems and product defects.

The effectiveness of vacuum flanges is augmented by the use of gaskets and sealing rings, which improve the seal integrity of the interface. Different types of flanges, such as ISO and ConFlat flanges, cater to varied demands and guidelines within the field. Understanding the various configurations and materials available assists engineers select the suitable vacuum flanges for their particular applications, ensuring optimal performance and functionality.

Applications in Different Industries

Vacuum fittings are essential in the semiconductor manufacturing industry, as maintaining sanitary conditions is necessary. These parts allow for the creation of vacuum systems that protect fragile equipment and ensure precision in the manufacturing of semiconductor devices. By providing effective seals and preventing contamination, vacuum flanges improve the efficiency and yield of semiconductor production processes.

In the pharma and biotech sectors, vacuum flanges are integral to multiple processes, particularly in the production of sterile products. They are employed to create vacuum conditions in sterilizers and other sterilization equipment, which enables effective microbial elimination. The ability to maintain a controlled environment ensures product integrity and adherence with rigorous regulatory standards, making vacuum flanges indispensable for these sectors.

The culinary sector also makes use of vacuum flanges in packaging and preservation methods. Vacuum sealing systems help to extend the shelf life of products by minimizing oxygen exposure, thus preventing spoilage. This application not only boosts food safety but also increases efficiency in manufacturing and distribution processes, showing the flexibility of vacuum flanges across different industrial applications.

Future Trends in Vacuum Technology

The future of vacuum technology is poised for major advancements, driven by the increasing demand for accuracy and efficiency in diverse industries. As manufacturers seek to refine their manufacturing processes, vacuum flanges are projected to play a vital role. The integration of intelligent technologies and Internet of Things (IoT) will facilitate for real-time monitoring and control of vacuum systems, allowing companies to optimize their operations and reduce downtime.

In addition, the development of materials that can endure higher temperatures and corrosive environments will expand the applications of vacuum flanges. Innovations in metallurgy and material science will yield lighter, sturdier, and more durable components that can operate efficiently in demanding conditions. This will not only enhance the performance of existing systems but also provide new opportunities for vacuum technologies in sectors such as aviation, pharmaceuticals, and energy.

Furthermore, sustainability will propel the advancement of vacuum technology. As industries concentrate on minimizing their environmental footprint, vacuum systems that use lower energy and have lower emissions will see traction. This includes the adoption of energy-efficient pumps and seal designs that lower leaks. The industry will probably see a transition towards increasingly eco-friendly materials in vacuum flanges, aligning with global trends towards sustainability and responsible manufacturing practices.